Your Artificial Grass More Sustainable with Reconnect

Your artificial grass more sustainable with Reconnect 21 June 2024 The environment is an issue that concerns our society, which is why Realturf works every day to offer the most sustainable options along with great quality and variety of colors so that your garden becomes your favorite place to reconnect with nature. On a daily […]

Pro Padel League Chooses Realturf as Its Official Playing Surface

13 June 2024 Finally, we can announce a great collaboration in the world of sport, more specifically in the world of artificial turf for padel courts. It is a new agreement that positions Realturf as the new official playing surface for the Pro Padel League (PPL), the only professional padel league in the United States. […]

Sekisui Alveo launches new version of Alveosport shock pad with a low-carbon footprint

Sekisui Alveo, European manufacturer of high-quality polyolefin foams, is known for innovation, also in terms of environmental performance. The latest development is the use of bio-circular base materials for making the company’s renowned Alveosport shock pad used in artificial turf systems and playground surfaces. With this new offering, Alveosport retains its proven technical performance and […]

Sekisui Alveo introduces innovative shockpad foam for non-infill systems

Sekisui Alveo, European manufacturer of high-quality polyolefin foams, has expanded its well-known Alveosport product line. Alveosport NUT 3011-14 is a new foam designed especially for use as a shockpad in artificial turf systems designed without infill. The innovative material not only meets the technical and quality requirements for sports fields, it presents an alternative to […]

Sport Group recycles synthetic turf in the future

The Sport Group is one of the world’s leading companies in the field of synthetic sports surfaces. With its subsidiary Polytan, the company has a high market share in the construction of artificial turf pitches and running tracks. Now the Bavarian company is also entering the recycling business. The newly founded subsidiary FormaTurf will turn […]

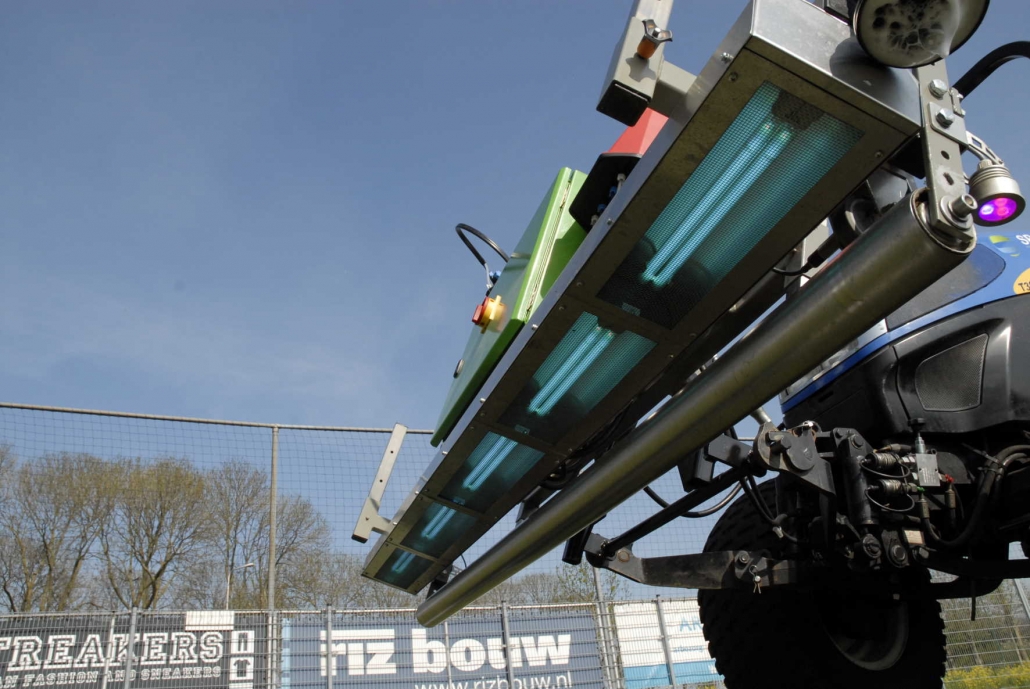

Risk minimization by irradiation to ultraviolet light

Recreational Systems International can confirm that its Rhenac Sports LED UV-C 600 technology is effective in disinfecting lawns. The mobile RHENAC UVC 600 lawn disinfector has been used for years to prevent the development of algae, fungi and other lawn diseases on sports turf. The system is working with UVC light, which is fundamentally suitable […]

RSI welcomes Markus Deimling

Recreational Systems International (RSI) has strengthened its LED Grass Grow technology for sports fields team in Germany by appointing Markus Deimling as new business manager for stadium pitch concepts . Deimling brings with close to 30 years’ experience in the flooring industry. The appointment of a Business Manager Stadium Pitch Concepts for the German speaking […]

RSI wins innovation tender; 100% recyclable artifical turf in the making

Dutch government tasks Recreational Systems International (RSI) with developing a truly 100% circular artificial turf. RSI has won a tender by the Dutch government to develop the artificial turf systems of the future. The new systems will be 100% recyclable, while also meeting the quality standards defined in the Quality Programmes issued by FIFA, World Rugby […]

The first CO2-neutral football turf

LigaTurf Cross GT synthetic turf made from bio-based plastic The first CO2-neutral football turf The LigaTurf Cross football turf has become an absolute model of success since it was launched on the market. The high demand it enjoys can be attributed to the special combination of smooth and textured synthetic turf fibres in one system. […]

High-tech sports surfaces made from sus-tainable raw materials

Polytan presented Green Technology at FSB 2019 High-tech sports surfaces made from sustainable raw materials How sustainable can modern high-tech sports surfaces made from synthetic material get? Polytan gave the answer to that question at this year’s FSB in Cologne, the leading international trade fair for public space, sports and leisure facilities. There the Burgheim-based […]