Schmitz Foam Products launches redesigned ProPlay® shock pad with reduced footprint

Schmitz Foam Products is the global supplier of high-quality ProPlay shock pads and has a reputation for its unrivalled solutions, innovation and quality. As of 1 January 2024, the company introduces its latest product: ProPlay-Sport23D/170. This improved variant replaces the successful ProPlay-Sport23D and can be manufactured with a more optimal mix of raw materials. The […]

Sustainable ProPlay shock pad now certified as subbase for field hockey fields in the Netherlands

ProPlay, the sustainable shock pad produced by Schmitz Foam Products, has been officially certified by the Dutch Hockey Association (KNHB) as a subbase for field hockey fields. When the Dutch hockey club RHC Concordia was forced to replace all their fields due to extreme flooding in July 2021, they wanted to invest in a durable […]

Schmitz Foam Products & the week of the Circular Economy

February 7th to the 12th was the Dutch week of the circular economy. The purpose of this week is to show how the circular economy works in practice. With a rising demand for resources worldwide, there is also a demand, if not a necessity, to handle these resources more responsibly. With this in mind, the […]

ProPlay-MP12 delivers a more economical and ecological solution

The ProPlay-MP12 shock pad for play areas, small-sided game areas and multi-game areas facilitates children experiencing the best and safest possible playing moments in the early stages of their lives. It also helps facility owners to improve their sustainability score and facilitates the establishment of more of these early-childhood development areas. Playing sports and games […]

EU Green Week – Member spotlight – Schmitz Foam

How Schmitz stays ahead of a changing synthetic turf market

Chief Technical Officer Ron Moors heads new Quality & Development department As of the 1st of March we have a new central department: Quality & Development, led by our CTO Ron Moors. With this new department, we will be able to anticipate even better the everchanging synthetic turf market Over the years, Schmitz has developed […]

Evolution of high quality shock pad is ahead of its time

The new ProPlay-Sport20 passes all tests The start of the new decade saw the ProPlay-Sport20 undergoing a update, this to ensure the world’s most popular shock pad is future-proof. 2020 turned out to be a year that was demanding in many ways, but the renewed ProPlay-Sport20 passed with distinction. ProPlay-Sport20 is widely praised for its […]

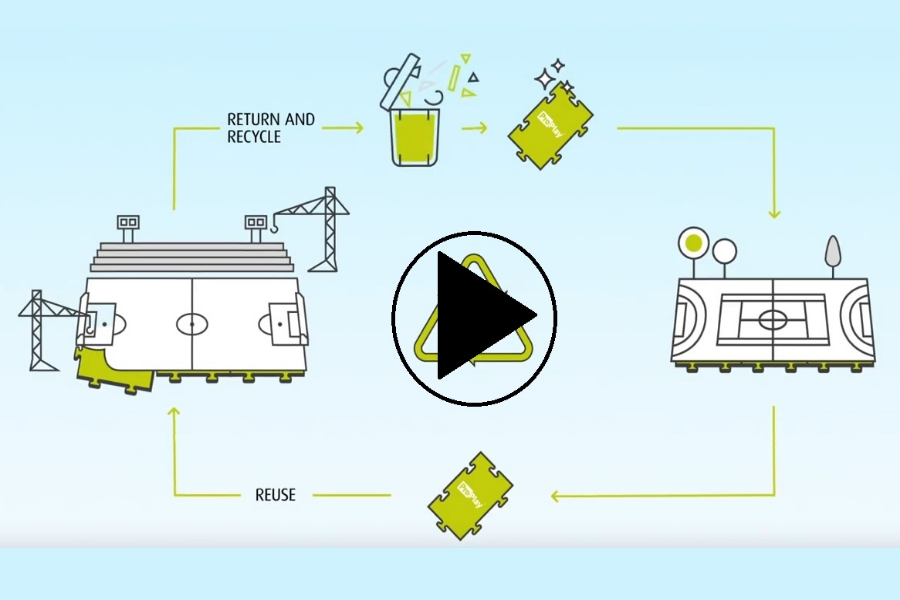

The continuous ProPlay loop of giving foam a purpose

ProPlay shock pads distinguish themselves in many ways, but one aspect that truly makes ProPlay stand out is its respect for the environment. ProPlay is made from redundant foams. Once these foams have been accepted for the production of this shock pad, they will remain in the system and will continuously be used to produce […]

Schmitz Foam Products replaces its popular ProPlay-Sport20

As of January 2020, Schmitz Foam Products will replace its popular ProPlay-Sport20 shock pad by a renewed version. The change is necessary to answer the demand for the product and to remain on par with the latest trends and developments. Schmitz Foam Products introduced ProPlay-Sport20 in the early 2000s, when shock pads were still considered […]