Sustainability & Recycling of Synthetic Turf Systems : the Future

THE SYNTHETIC TURF INDUSTRY IS AT A CROSSROAD. WHY? Public awareness of the damage caused by plastic waste in the environment means that manufacturing strategies that do not reduce the impact of production on the environment will soon become unacceptable. Of course, synthetic turf systems and shock pads will fall under the broad banner of […]

Sport Group recycles synthetic turf in the future

The Sport Group is one of the world’s leading companies in the field of synthetic sports surfaces. With its subsidiary Polytan, the company has a high market share in the construction of artificial turf pitches and running tracks. Now the Bavarian company is also entering the recycling business. The newly founded subsidiary FormaTurf will turn […]

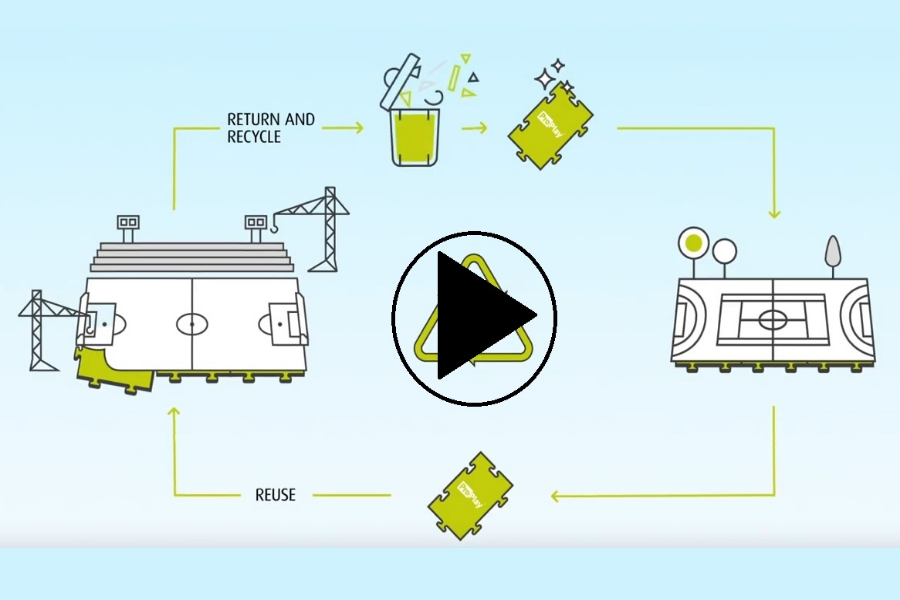

The continuous ProPlay loop of giving foam a purpose

ProPlay shock pads distinguish themselves in many ways, but one aspect that truly makes ProPlay stand out is its respect for the environment. ProPlay is made from redundant foams. Once these foams have been accepted for the production of this shock pad, they will remain in the system and will continuously be used to produce […]

Webinar European development towards biodegradable polymers

On the 28th of October Senbis Polymer Innovations will co-host a Chemport Europe webinar on the market opportunities for innovations with biodegradable polymers due to a microplastic legislation proposal by the European Chemicals Agency. As an example case for the artificial grass market, Ten Cate Grass executives will elaborate their approach. Register via: https://lnkd.in/gSS9W_P

Limonta Sport obtains certification for 100% natural infill

Limonta Sport obtained the OK BIOBASE and OK BIODEGRADABLE certification from the TÜV Austria Institute for their GEO, a 100% natural performance infill. Andrea Marcassoli, R&D Manager explains : “A certification based on European standards EN13432 and EN14995 relating to compostability confirms that GEO is 100% biodegradable in the soil, and EN16640 on which the […]

GBN AGR officially certified to recycle end-of-use synthetic turf

GBN AGR has received the first unique certificate for the recycling process of End of Life artificial grass from Kiwa. The certification process is conducted by quality assurance institute Kiwa. Kiwa is an autonomous global organization in Testing, Inspection and Certification. Kiwa is strictly independent and not involved in manufacturing, trading or other activities that […]

Sports and Leisure Group nominated for 2020 Export Lion Award

Sports & Leisure Group (Domo Sports Grass) is honoured and excited to be nominated for the prestigious Leeuw van de Export award. Flanders Investment & Trade – FIT awards this prize to Flemish companies with outstanding export results. We are proud to receive this nomination, just as we are proud of our export performance year […]

Superior Limonta Sport rugby field for Asd Pesaro Rugby

Asd Pesaro Rugby was founded in 1969 thanks to Tonino Uguccioni, the quintessential President who in 2007 was awarded the “Golden Oval” (Ovale d’oro) by the Italian Rugby Federation, an accolade reserved for those individuals who work to develop rugby. The club, currently in the Second Division, played in the top Championship Division for the […]

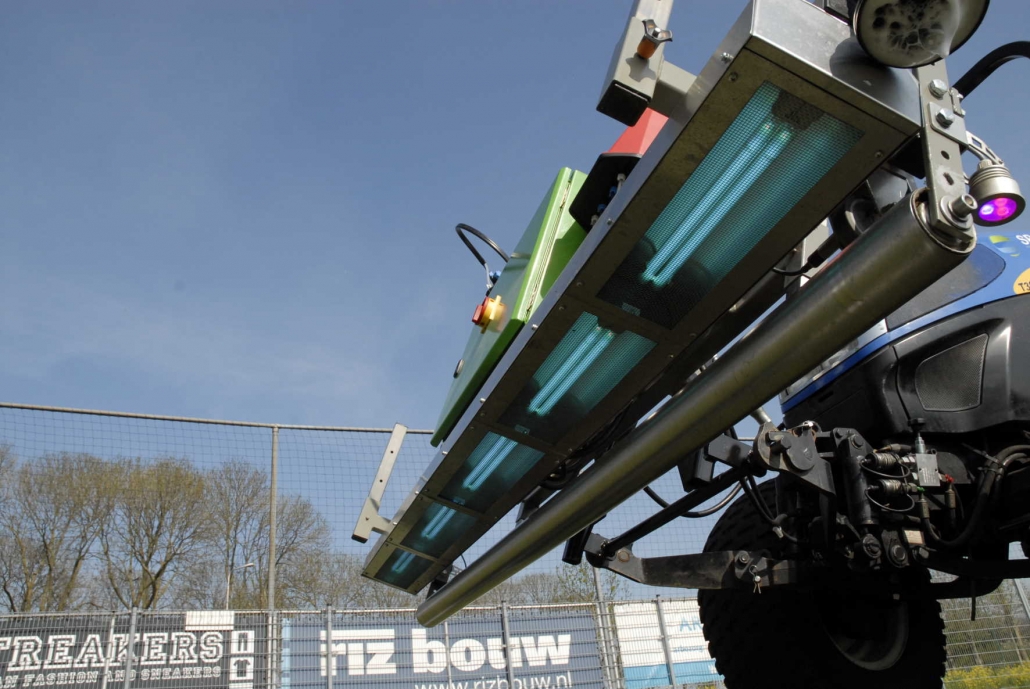

Risk minimization by irradiation to ultraviolet light

Recreational Systems International can confirm that its Rhenac Sports LED UV-C 600 technology is effective in disinfecting lawns. The mobile RHENAC UVC 600 lawn disinfector has been used for years to prevent the development of algae, fungi and other lawn diseases on sports turf. The system is working with UVC light, which is fundamentally suitable […]

ProGame XC Series Shock Pad patented

ProGame XC Series shock pad provides a unique patented solution for sports pitch systems. ProGame XC shock pads have achieved full patent protection of the product and process in manufacturing. The full patent status for the XC Series recognises the unique features and performance of the XC Series shock pad product in artificial pitch systems. […]